Rapid LIBS Mineral and Elemental Scanning with Elemission ECORE

Elemission ECORE

Elemission is a world leader in applying LIBS technology in industry, particularly when applied to geological materials. Their latest development is The ECORE marries automation with their proven LIBS workflow and SAM (Smart Automated Mineralogy) AI-enabled software, the ECORE is designed to measure trays of core, chips or powder samples at high-speed, greater than 2000m/day.

With the intention of being field deployable, the ECORE can determine such things as mineralogy, multi-element chemical assays, automated lithology, elemental deportment, mineralogical texture, grains size and more.

Advantages of LIBS

LIBS produces elemental data similar to XRF but with from smaller spot sizes enabling mapping of geological materials such as drill core with high degrees of accuracy. Most importantly, LIBS is suitable for every element in the periodic table, making it the superior solution for those involved in lithium exploration and mining. Another key advantage of LIBS is there is little to no sample preparation required and the data can be collected in situ.

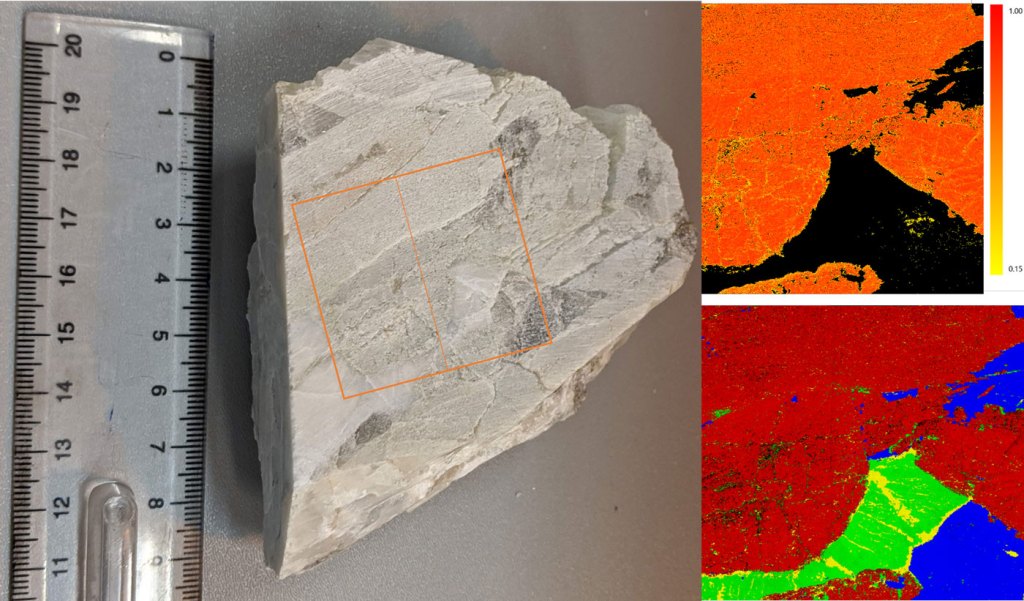

LIBS quantitative mineralogy of LCT pegmatite: 6 min at 50 µm resolution.

How Does LIBS Work?

A LIBS analyser shoots a high-energy laser pulse at a sample forming a plasma consisting of highly excited atoms and ions. As these excited entities return to their ground state, they emit light of a characteristic wavelength. By looking at the resultant emission, the spectrometer can determine which elements are present and in what proportions and hence determine the mineralogic composition.

The combination of high frequency lasers and high-speed detectors allows LIBS systems to take more than 1300 readings per second facilitating high-speed core analysis.

LIBS as Automated Mineralogy

Using a database of typical spectra, each spot measured by LIBS can be related back to a single mineralogical phase. By shooting a large number of spots, mapping or microanalysis of the sample can be performed, revealing mineral distributions and concentrations. The image below compares LIBS analysis to analysis via Scanning Electron Microscopy and Energy Dispersive Spectroscopy (SEM/EDS), a well-accepted automated mineralogy technique.

Optical microscope image of a PGE drill core sample (left), LIBS map (centre) and SEM/EDS map of the same sample/region of interest.

As can be seen, the mineralogical analyses are very similar. However, the LIBS analysis can be completed in a faction of the time. Furthermore, it is also possible to measure as-received samples, using LIBS, resulting in further workflow efficiencies.

Typical data output from the Elemission ECORE. Waterfall plots for a PGE sample including optical images indexed against a mineral map, quantified mineralogy as well as gold content.

CSIRO Invest in LIBS CORE Scanning

CSIRO’s Dr. Adam Bath described Elemission’s hardware as being “fit for purpose” and if their project with gold producer Northern Star Resources is successful “could redefine the role of geologists”. Currently, analysis of core by geologists can be quite subjective. Using LIBS, removes this providing much more consistent analyses. Adoption of onsite LIBS would free geologists to be available for more critical issues such as assessing mineral and alteration patterns, while real-time data production would allow them to react more quickly saving time and money.

AMI offers ECORE Scanning Access

Elemission’s ECORE is available for evaluation at the Automated Mineralogy Incubator (AMI). The AMI offers industry access to cutting-edge technologies like the ECORE supported by a team of world-class mineralogist who will help you understand how the technology can be integrated into your specific workflow bringing about improved efficiencies.

Summary

Accurate and timely geochemical and mineralogical analysis of mineral deposits are critical in assessing their economic viability and optimisation of processing. Rapid drill core scanning using LIBS, coupled with software with automated mineralogy capabilities provides the capability to not only evaluate mineral deposits, but also to provide valuable information that can influence and optimise extraction processes.

LIBS technology for geo-related applications has matured to the stage where commercial products already exist that offer ultra-fast automated mineral phase identification and quantification. The technology is proven and early adopters will reap the benefits of improved exploration programs and metallurgical processing with increased efficiency. In the very near future, LIBS will become a practical tool that can be used in high-production mine environments.

The AMI is currently providing LIBS analaysis to several mining companies. If you are interested in how this technology could benefit your operation, please contact us.

Further Reading

- LIBS core imaging at kHz speed: Paving the way for real-time geochemical applications, Rifai et al, Spectrochimica Acta Part B: Atomic Spectroscopy, Vol.150, Dec. 2018, 43-48.

- Emergences of New Technology for Ultrafast Automated Mineral Phase Identification and Quantitative Analysis Using the CORIOSITY Laser-Induced Breakdown Spectroscopy (LIBS) System, Rifai et al, Minerals, Vol. 10, Iss. 10, Oct. 2020, 918.

- Ultrafast Elemental Mapping of Platinum Group Elements and Mineral Identification in Platinum-Palladium Ore Using Laser Induced Breakdown Spectroscopy, Rifai et al., Minerals, Vol. 10, Iss. 3, Feb. 2020, 207.